2023-05-19

2023-05-19Throughout the developed countries, there are two stages in the effective application of combustible waste in the cement industry, that is, the initial stage of co-processing in cement kilns and the advanced stage of application of "alternative fuels".

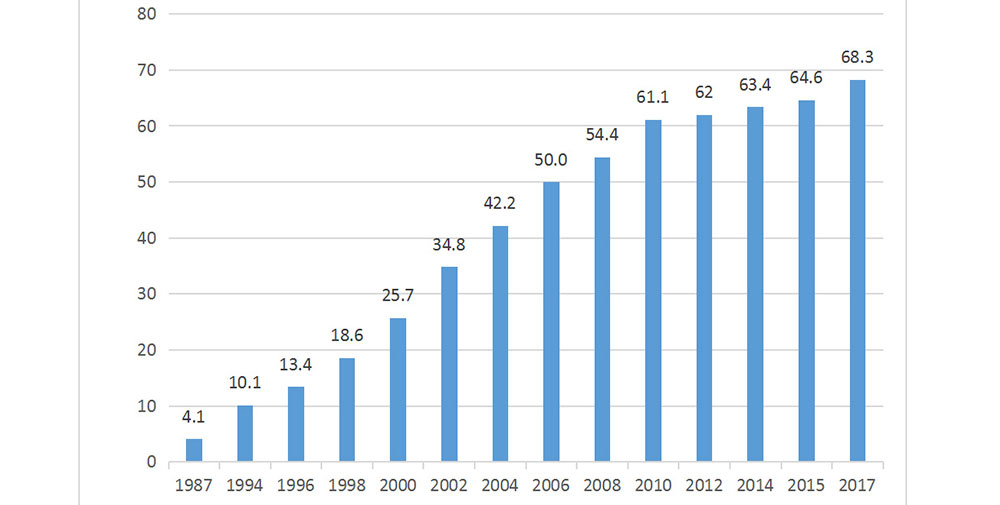

Studying the development history of the German cement industry, you will find an interesting content: Germany also used cement kilns to co-process combustible waste in 1985, and its heat replacement rate TSR was very low, about 2%. Obviously, it is basically the same as the current situation in our country. However, after that, cement kilns began to enter the advanced stage of using alternative fuels, and their efficiency increased rapidly. The heat replacement rate TSR increased from 4.1% in 1987 to 68.3% in 2017, achieving a qualitative leap.

Changes in TSR% of heat replacement rate in Germany from 1987 to 2017

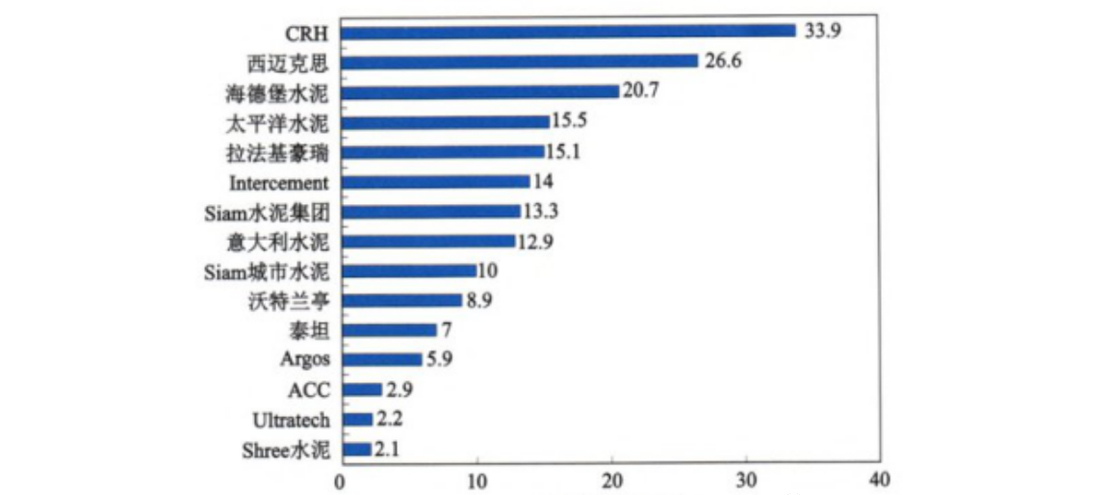

Fuel substitution technology is currently a relatively mature coal-saving and efficiency-enhancing technology in the cement industry. From a global perspective, Europe is in a leading position, with a TSR of about 39% for alternative fuels, followed by Brazil and North America at about 5%, while my country's cement industry has a TSR of less than 2%, a high value. was 7.46%.

Heat substitution efficiency of large cement groups:

The reason is that the current development of fuel substitution technology in my country's cement industry is still in the stage of using cement kiln co-processing technology. The "alternative fuel" produced by the cement kiln co-processing production line built by most cement enterprises is not high-quality due to the pretreatment and disposal of waste, which leads to large fluctuations in the calorific value of the "alternative fuel" produced, which has a great impact on the operation of the cement clinker production line. Internationally recognized quality standards for alternative fuels have not been met.

In 2020, in the "Industrial Structure Adjustment Guidance Catalog" issued and officially implemented by the National Development and Reform Commission, the key encouragement projects are specifically proposed in the category of encouragement: "Cement kiln co-processing", "Alternative fuel preparation technology" and other eight items, It clarifies the development direction for technological innovation and structural adjustment of the cement industry. At the same time, this also separates "cement kiln co-processing" from "alternative fuel preparation technology", which is proposed as two technical contents, explaining that cement kiln co-processing is "combustible waste" rather than "alternative fuel".

Then, in order to turn "combustible waste" into "alternative fuel" with high calorific value, it becomes the key to technological upgrading. Domestic Stride Environmental Protection Technology submitted a "high score answer sheet" in the preparation of SRF alternative fuels!

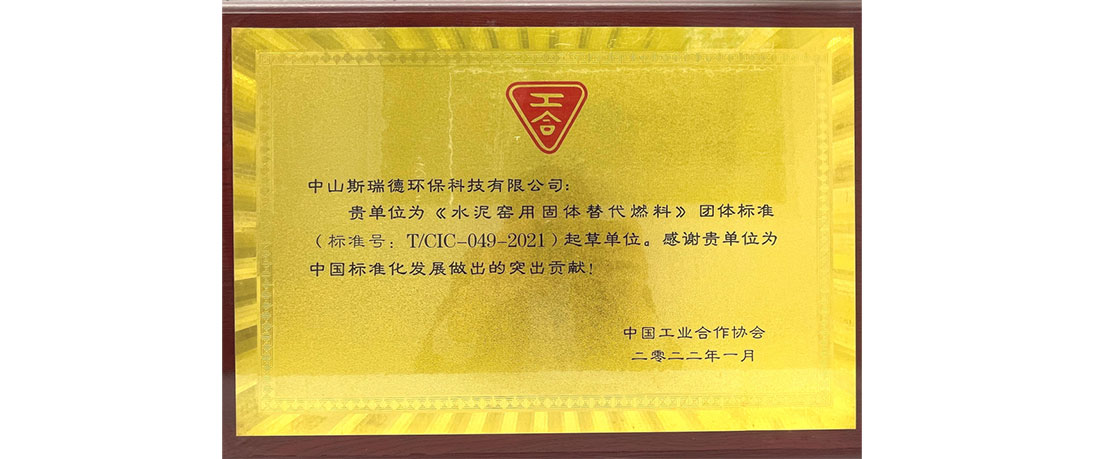

In 2021, Stride Environmental Technology participated in the drafting of domestic SRF alternative fuel group standards, namely "Definition and Classification of Solid Alternative Fuels", "Technical Specifications for Preparation of Solid Alternative Fuels", "Solid Alternative Fuels for Cement Kilns" and "Firepower "Solid Alternative Fuels for Power Generation", helping alternative fuels to enter the road of standardization and standardized development.

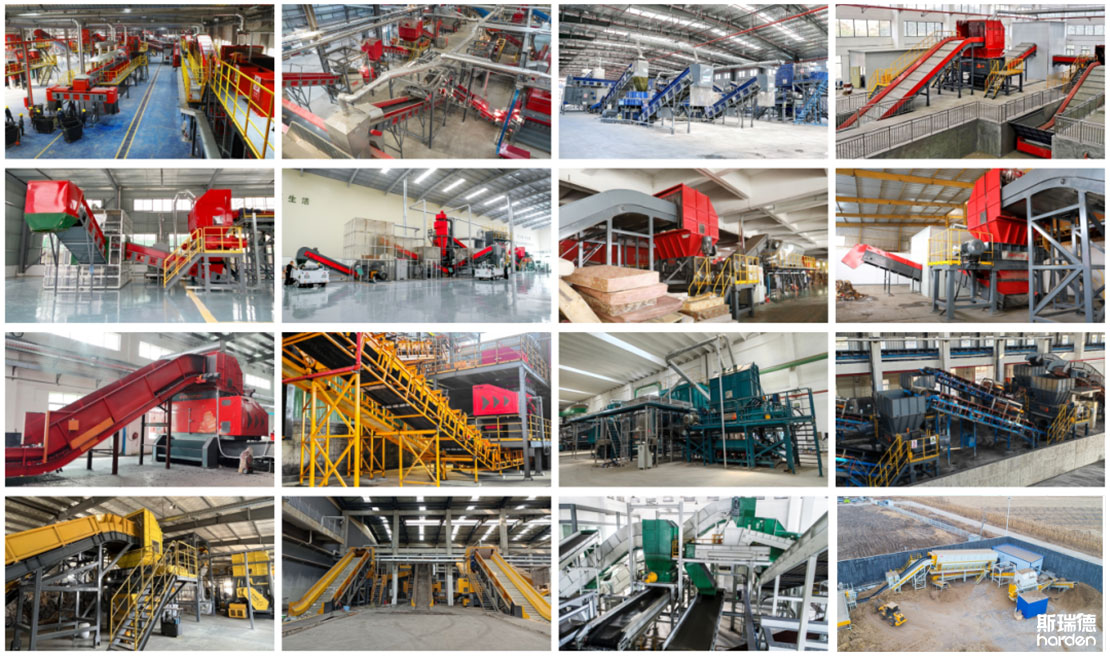

Harden integrates Germany's cutting-edge solid waste technology concept, targeting combustible waste in various domestic fields, such as domestic waste, general industrial solid waste, paper waste, bulky waste, stale waste, waste tires, biomass, etc. Through in-depth experiments and continuous innovative research and development, the SRF alternative fuel preparation system has been successfully built.

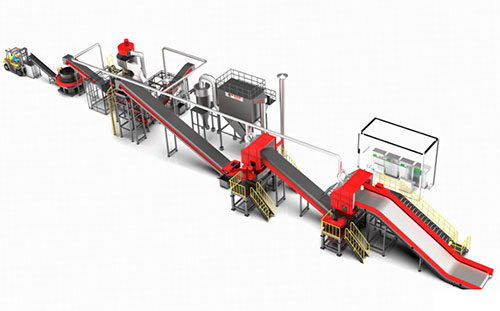

General industrial solid waste alternative fuel preparation system

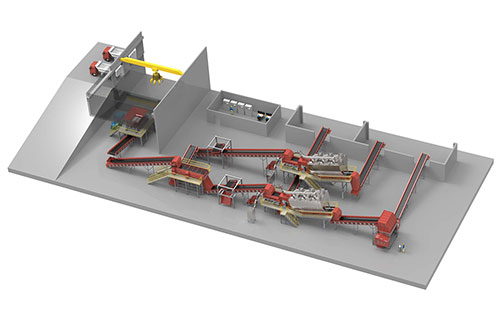

Bulky Waste Alternative Fuel Preparation System

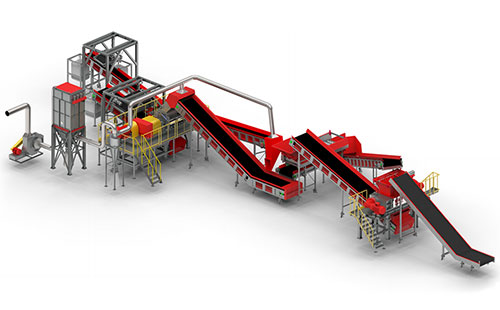

Domestic waste alternative fuel preparation system

Biomass Alternative Fuel Preparation System

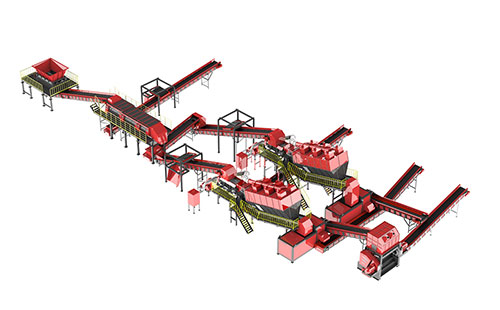

Waste tire alternative fuel preparation system

Stale Waste Alternative Fuel Preparation System

Harden's SRF alternative fuel preparation cases in various fields: