2023-04-28

2023-04-28In order to actively adapt to the dual-carbon strategy and control the cost of coal use, a cement company conducted a series of data monitoring for a period of one month after adopting SRF alternative fuels, and analyzed the actual effect of SRF alternative fuels on cost reduction and energy saving with the resulting data.

[Monitoring time] September 2022 (one month)

[Alternative fuels] The total trial volume is 531 tons, mainly from the Guangdong region. It is composed of clothing scraps, waste clothes and sponges, all of which are used after recycling.

[Sampling method] The frequency is once every two days. The sampling location is the quantitative feeder. Each sampling time is 1 hour, and the sample is taken every 15 minutes. Finally, the four samples are mixed as the current comprehensive sample. A total of 6 samples were taken in this experiment, numbered 1-6 in sequence.

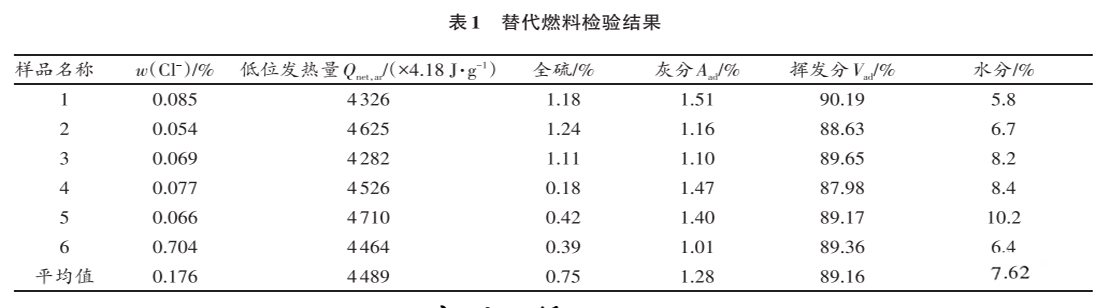

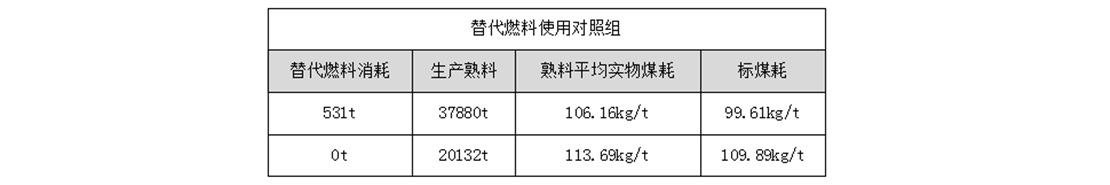

① The average low calorific value of SRF alternative fuel is 4489cal/g, and the average moisture content is 7.62%;

② The calorific value of pulverized coal is 6476cal/g, and the average moisture content is 2.45%.

Converted according to the low calorific value, theoretically 1.55 t of this type of alternative fuel can replace 1 t of pulverized coal.

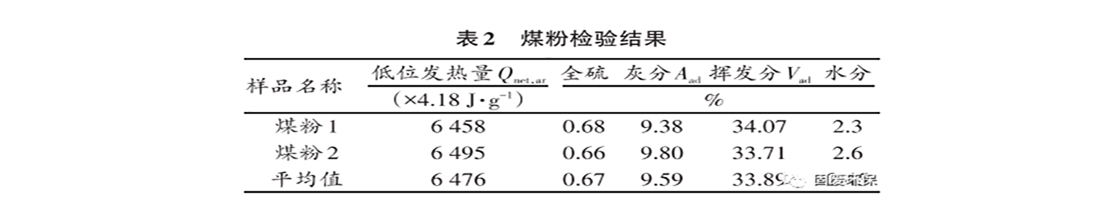

From the change trend of tailing coal before and after the use of alternative fuels, it can be found that after using alternative fuels, the amount of tailing coal is significantly reduced. There is a positive correlation between the feeding amount of alternative fuels and the amount of coal saving.

Based on the above data, the standard coal consumption per ton of clinker is reduced by 10.28kg during the period of using alternative fuels. The actual coal-fired substitution rate of alternative fuels is 1.86%, so every 1.86t of alternative fuels can save 1t of pulverized coal.

Data Results Cost Analysis

Cost analysis based on the data in September 2022: the total consumption of alternative fuels is 531t, the calorific value is calculated as 4500cal/g, the price of alternative fuels is 500 yuan/t, the actual substitution rate is 1.863, and 285.02t of pulverized coal is replaced, which will enter the plant in September The price of raw coal (including tax) is 1469.62 yuan/t, and the conversion ratio of raw coal cost and pulverized coal cost is converted according to the calorific value of coal (raw coal: pulverized coal = 1.1:1); the final cost saving (tax included) is 194,800 yuan.

According to national regulations, an emission fee of 50 yuan is required for every 1 tCO2 emitted. During September, the CO2 emitted by alternative fuels is calculated based on the emission value of the alternative pulverized coal, which can save 26,236.34 yuan in emission fees.

Cost savings after only using 531 tons of SRF as an alternative fuel:

19.48+2.62=221,000 yuan

The company's coal consumption from January to July was 105.95kg/t. After using 531t of alternative fuels in September, the standard coal consumption was 102.39kg/t, a decrease of 3.56kg/t. That is, every 149 tons of alternative fuel used can increase the standard coal consumption by 1kg/t.

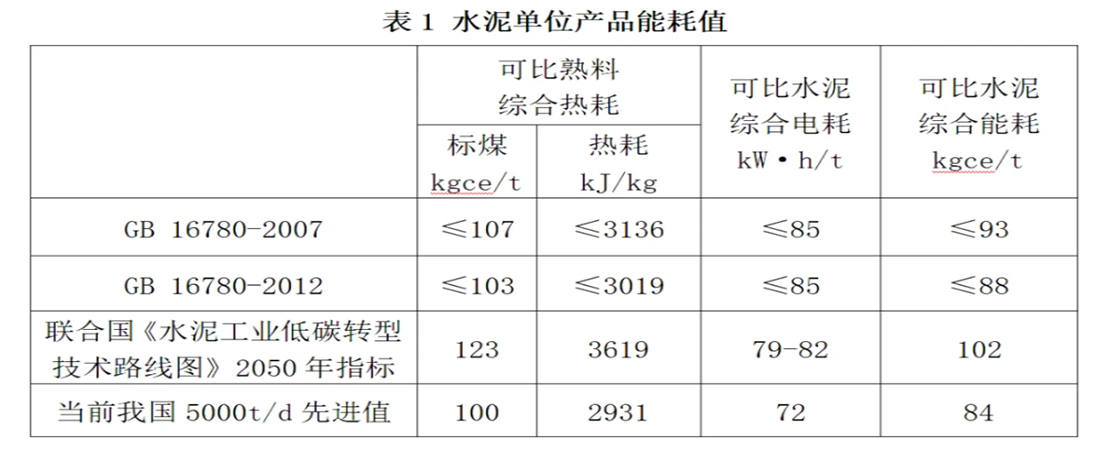

Interestingly, according to the "Energy Efficiency Benchmark Level and Baseline Level in Key Areas of High Energy Consumption Industries (2021 Edition)", the energy efficiency benchmark level of cement clinker is 100 kg standard coal/ton, and the benchmark level is 117 kg standard coal/ton. If the use of alternative fuels is increased, the level of energy efficiency can be greatly improved, so as to achieve the goal of "the proportion of clinker production capacity above the energy efficiency benchmark level of the cement industry will reach 30% by 2025".

To sum up, each ton of SRF alternative fuel can save 416 yuan in cost, and can effectively improve the energy efficiency level.

The company only used 531 tons of SRF alternative fuel in the test, and there is huge room for improvement in the future. It can not only increase the feeding amount of alternative fuel, but also adopt better alternative fuel preparation technology to control the moisture content and size of alternative fuel. The size can greatly increase the average combustion calorific value of alternative fuels to improve the economic benefits brought by alternative fuels.

Zhongshan Stride Environmental Protection Technology has been deeply involved in the solid waste treatment industry for more than ten years. It has SRF alternative fuel preparation in the fields of domestic waste, bulky waste, paper mill waste, stale waste, general industrial solid waste, waste tires, agricultural and forestry waste, etc. overall solution.

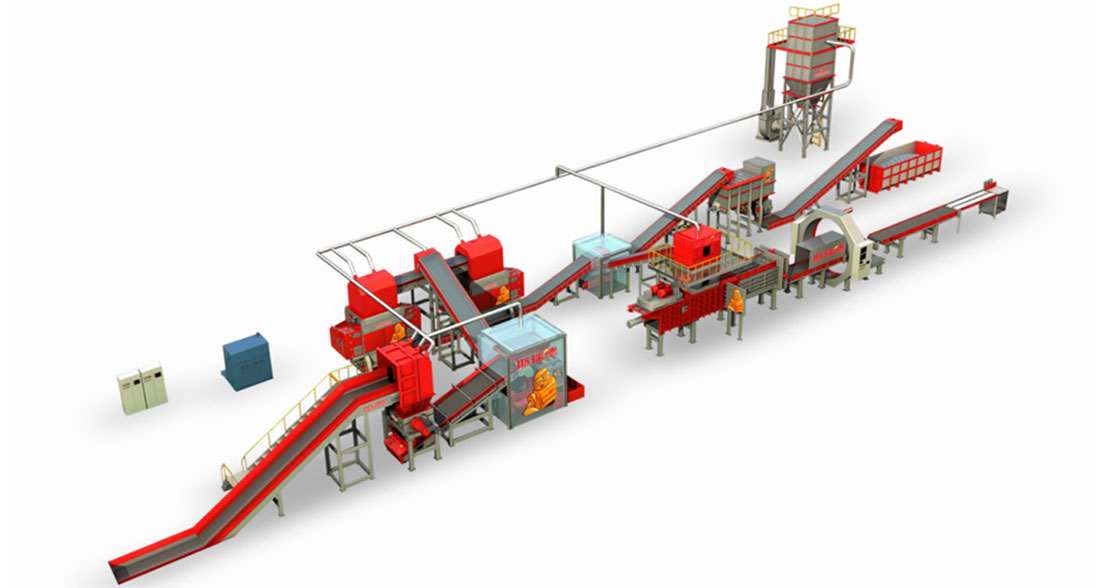

General industrial solid waste SRF alternative fuel preparation system

Streider integrates Germany's cutting-edge solid waste treatment technology concepts, relies on continuous innovation of independent research and development capabilities, and through "two-stage crushing + magnetic separation + winnowing + sorting + dust removal" and other processes, the obtained SRF alternative fuels are discharged The size and degree of homogenization have been greatly improved, the heat loss coefficient is lower, and the average combustion calorific value of alternative fuels has reached 4800-5200 kcal.

①Moisture content: The moisture content of alternative fuels made from different raw materials varies greatly, while the moisture content of alternative fuels prepared by Stride Alternative Fuel Technology is basically lower than 5%.

② Size: According to the modular combination of different processes, according to the needs of customers, Stride divides the output size into ≤30mm, ≤50mm, ≤80mm, ≤120mm, which is more humanized.

SRF Alternative Fuels:

HARDEN-SRF alternative fuel preparation system case:

Under the background of the national "dual carbon" strategy, "reducing energy consumption and saving costs" has become the primary goal of all enterprises in the cement industry. How to prepare solid waste into higher-quality SRF alternative fuels, and gradually replace the use of fossil fuels, will be a new outlet for energy use innovation in the future.