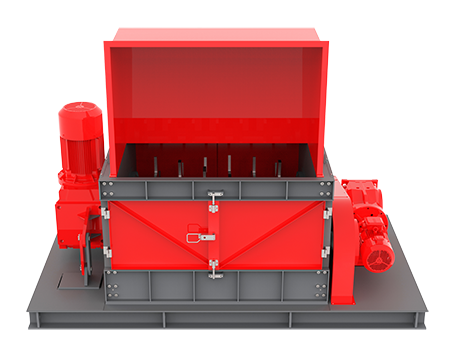

Product introduction

The disc screen from Harden is a professional sorting machine which distinguishes different size and shape material by disc rolling. When the machine is working, all the polygonal discs rotate in the same direction with the roller, so that the materials on the polygonal discs realize the compound movement of horizontal and tumbling, which makes the materials looser, and the materials are hit and spread by the rotating polygonal discs and do jumping and tumbling. When the particle size of the materials in the process of movement is less than the disc gap, it will be left out from the side gap of the disc, so as to achieve the screening function.

Product characteristics

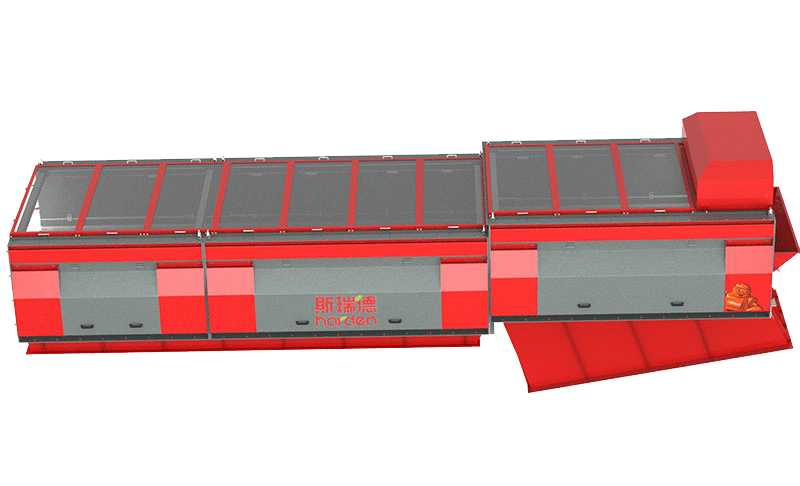

01.

Modular design

Unit modular design makes shipment convenient | High production capacity with low floor area | Open type screening surface leads to maintenance friendly

02.

Hexagonal or octagonal arc disc design

Modular design | Customized disc quantity | Maintenance friendly

03.

Adjustable mesh screen

10-200mm adjustment depends on material property an screen purpose

04.

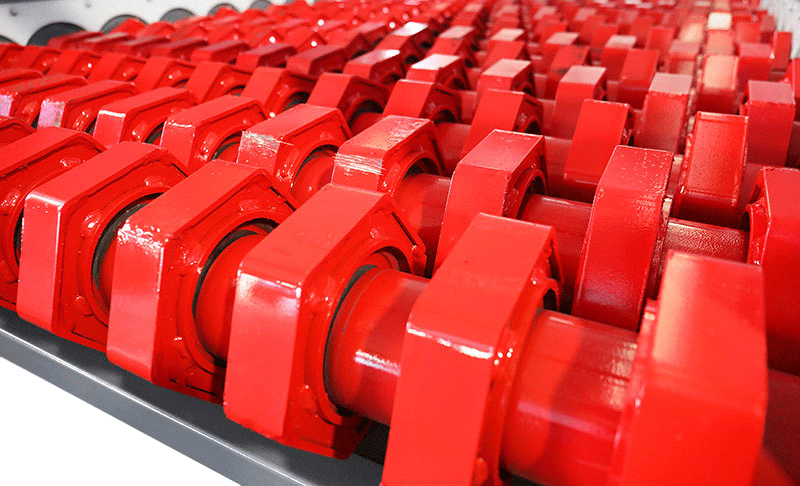

Patented multi-layer sleeve design

Anti-blocking structure | Patented anti-winding design aims at large mesh screen

05.

Infinitely variable speed control by variable frequency

Low energy cost | High safety performance

06.

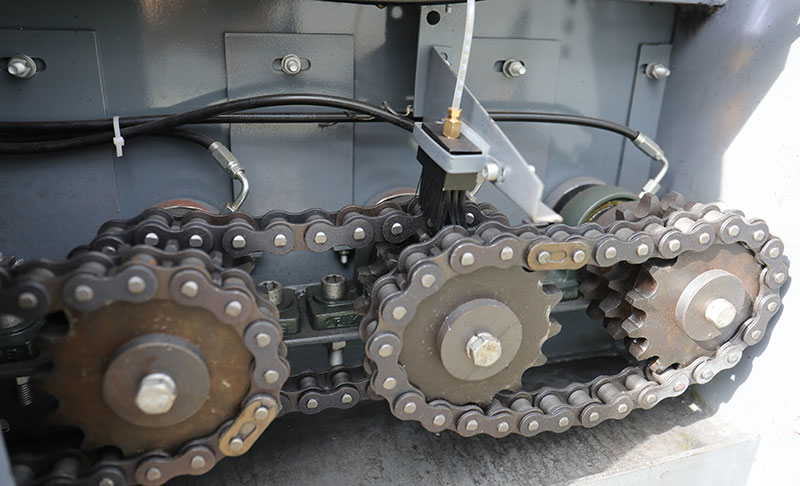

Wear-resistant chain linkage

Unique tension chain design | Stable operation

Scope of application

Sorting effect

Effect before sorting

Effect after sorting

Sorting cases

Product parameters

| Model | SDS1630 | SDS1650 |

| Motor Power(KW) | 5.5-7.5 | 11-15 |

| Motor Quantity | 1 | 2 |

| Operation Area Dimension(L*W) | 3*1.6m | 5*1.6m |

| Capacity Design(T/H) | 15-20 | 30-40 |

| Mesh Screen Dimension(mm) | 20-350 | 20-350 |

| Electrical Control | Variable Frequency | Variable Frequency |

| Machine Weight(KG) | ~3000 | ~5500 |

| (The capacity is calculated according to the density of municipal solid waste 350kg/m³and the mesh size of 80mm) | ||