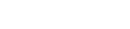

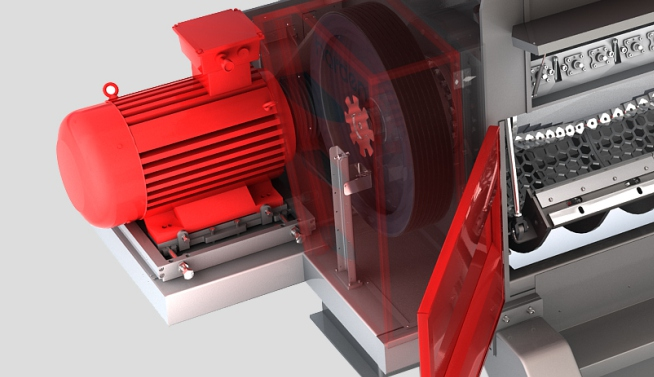

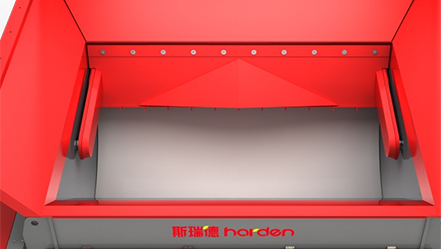

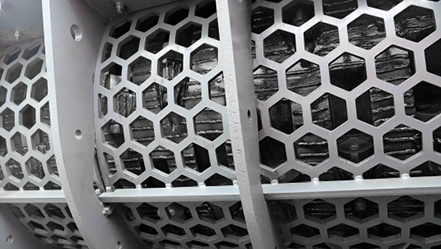

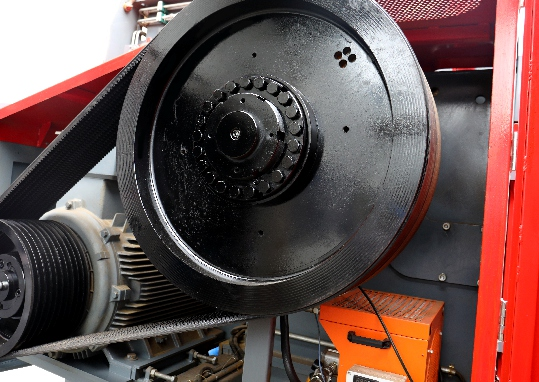

HARDEN SG series large-scale single-shaft fine shredder integrates multiple patented technologies such as intelligent built-in arc pressing, extremely small gap shearing, close-packed granule shaft, and rapid gap adjustment. Adopting advanced European design ideas and concepts, we have pursued greater output, lower operating costs, less maintenance time, and a safer and more user-friendly operating experience from the beginning of the design.

HARDEN has accumulated rich experience in single-shaft shredder. For different material processing, it has corresponding parameter configurations for torque, speed, action program, and size configuration. Whether it is raw materials such as flexible and high-strength leather fabrics or low-density lightweight materials, the single-shaft shredder can handle it calmly with excellent processing effects and production capacity.

What Distinguishes The

Single Shaft Shredder-SG Series

What Materials Can Be Shredded?

Advantages At A Glance

Our Case

Specific Parameter

-

SG2200RPDimensions (L*W*H)(mm)6122*3430*5423Total Weight (kg)28000Cutting Length (mm)2200View MoreRotor Speed (rpm)280Cutting System TypePNumber of Rotor Knives (pcs)90/120Number of Counter Knives (pcs)12Screens (pcs)3Power (kW)2*160Hydraulic Power (kW)15Drive ControlFrequency Converter

-

SG3000RPDimensions (L*W*H)(mm)6822*3430*5423Total Weight (kg)34000Cutting Length (mm)3000View MoreRotor Speed (rpm)280Cutting System TypePNumber of Rotor Knives (pcs)100/120/160Number of Counter Knives (pcs)16Screens (pcs)8Power (kW)2*200/2*250Hydraulic Power (kW)15Drive ControlFrequency Converter

-

SG3000RFDimensions (L*W*H)(mm)7430*2876*5200Total Weight (kg)34000Cutting Length (mm)3000View MoreRotor Speed (rpm)280/373Cutting System TypeFNumber of Rotor Knives (pcs)80/112Number of Counter Knives (pcs)16+16Screens (pcs)8Power (kW)2*200/2*250Hydraulic Power (kW)15Drive ControlFrequency Converter