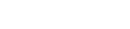

Wind shifter

Double Drum Windshifter

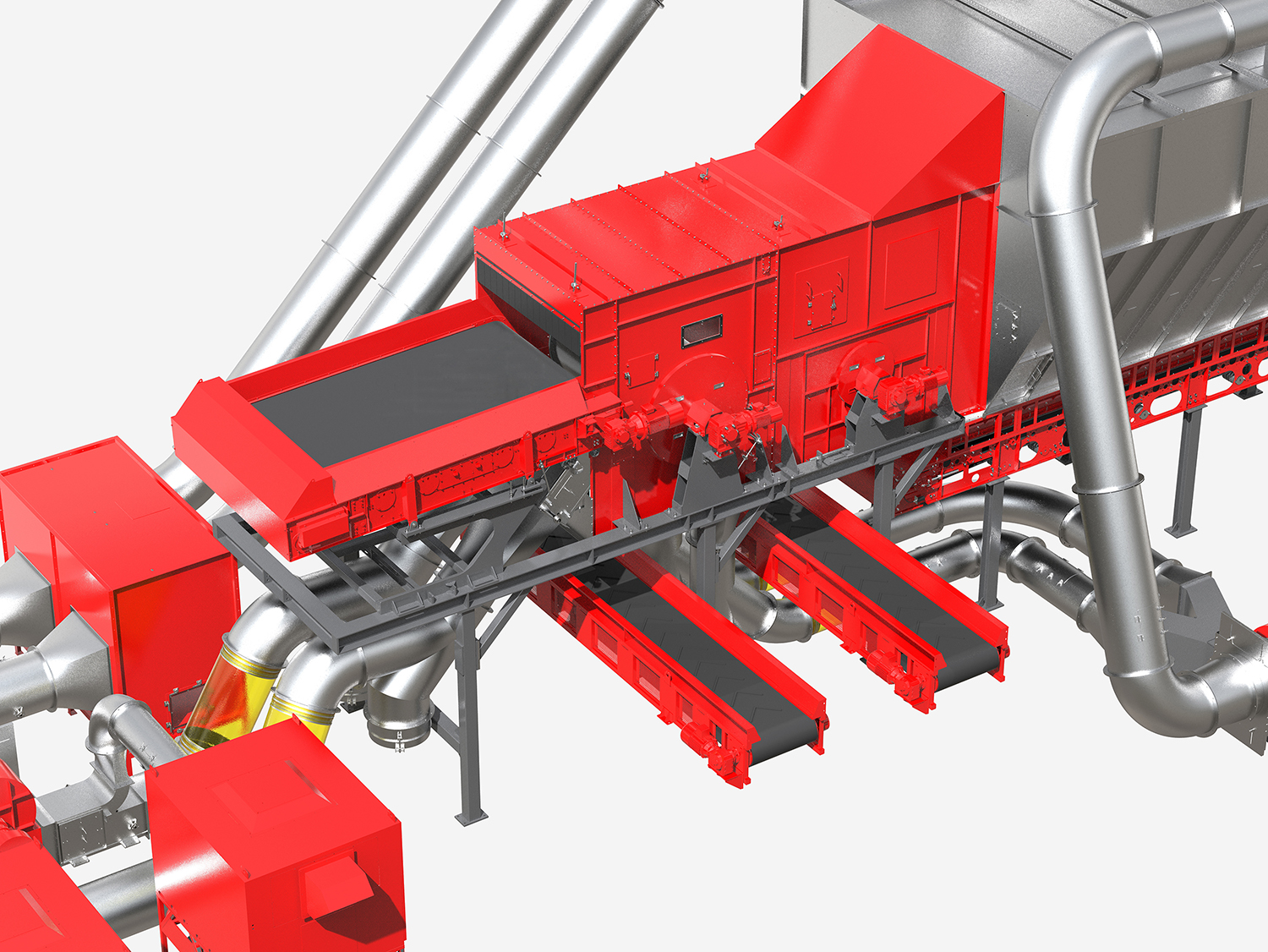

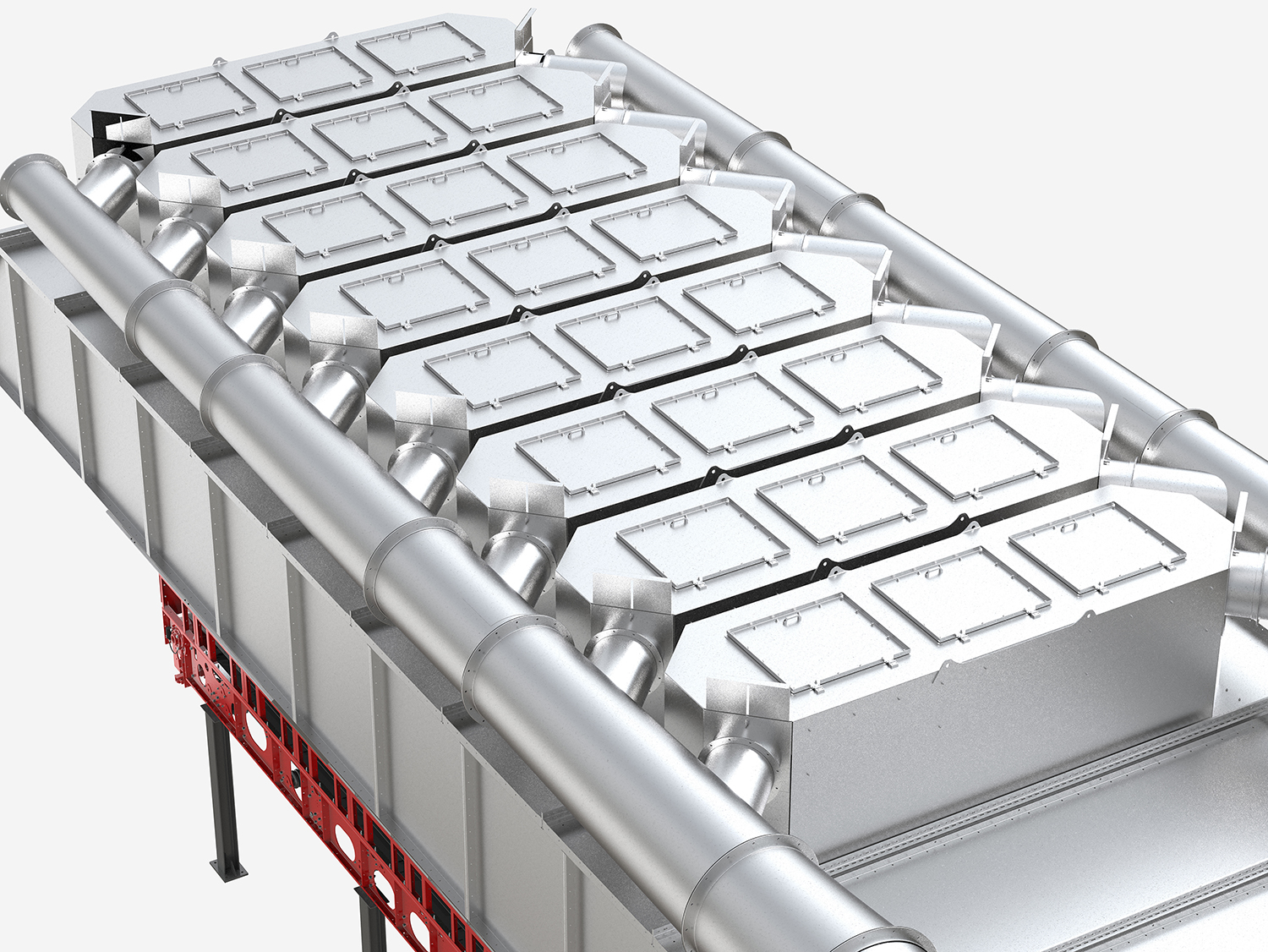

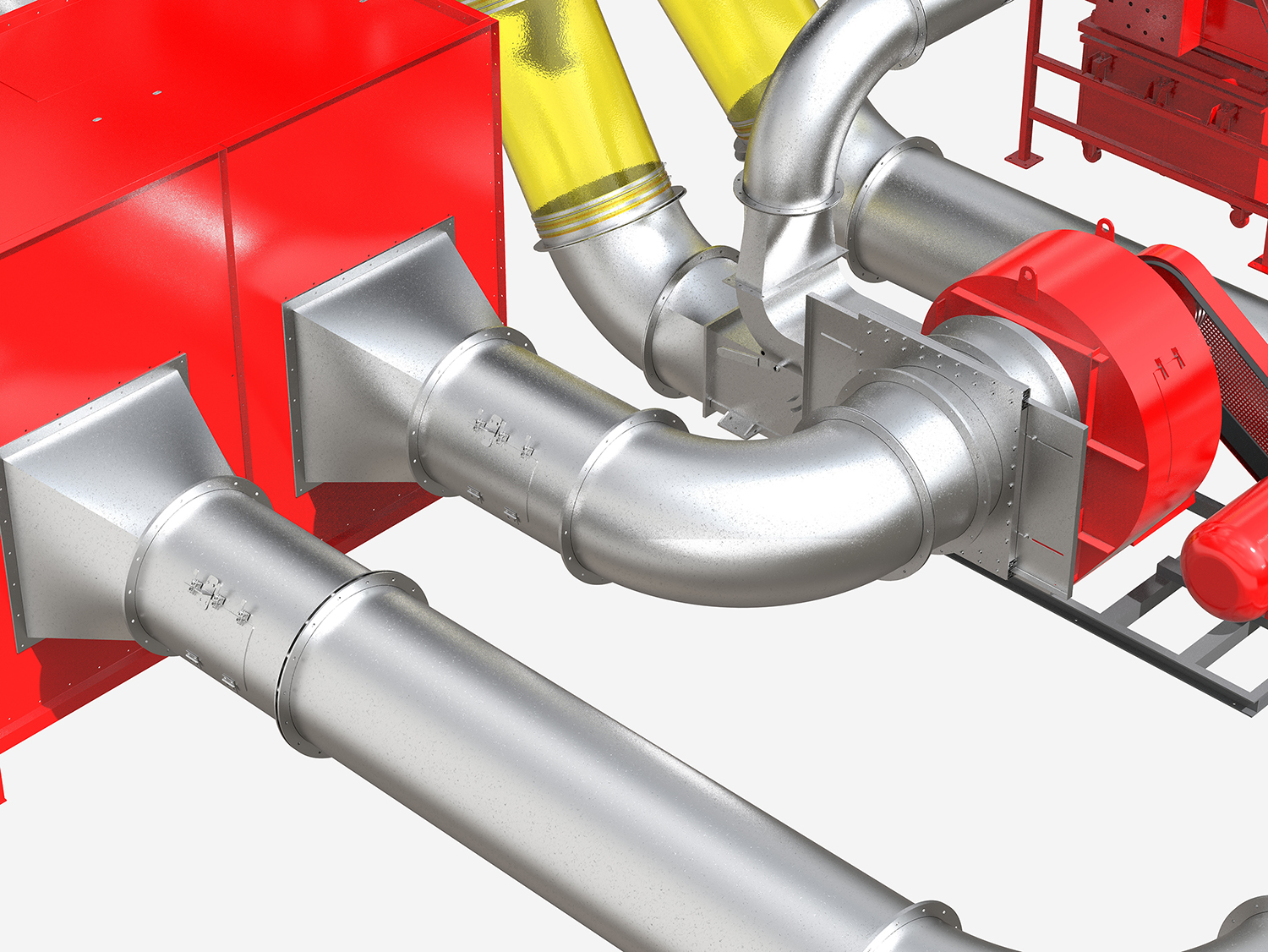

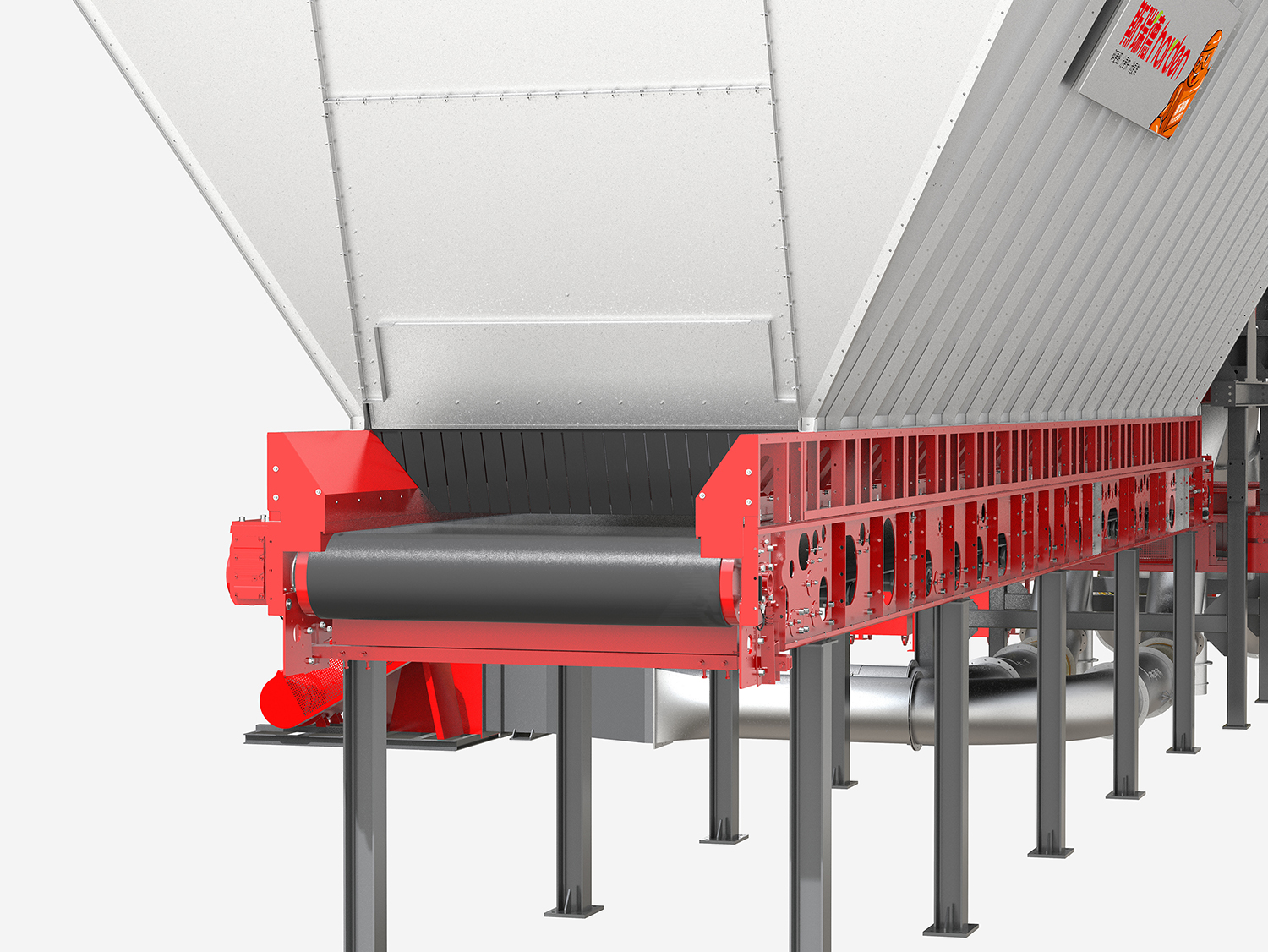

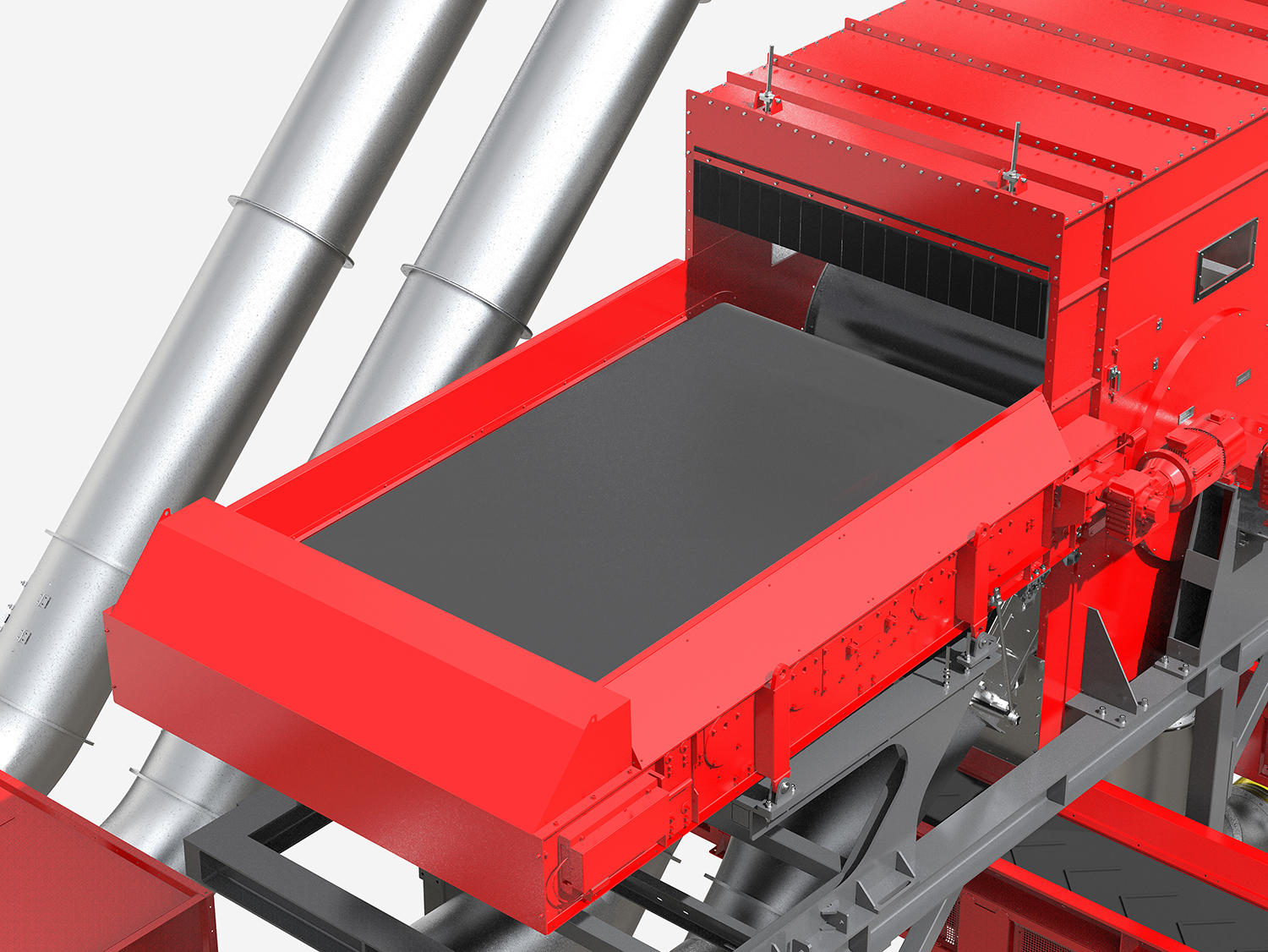

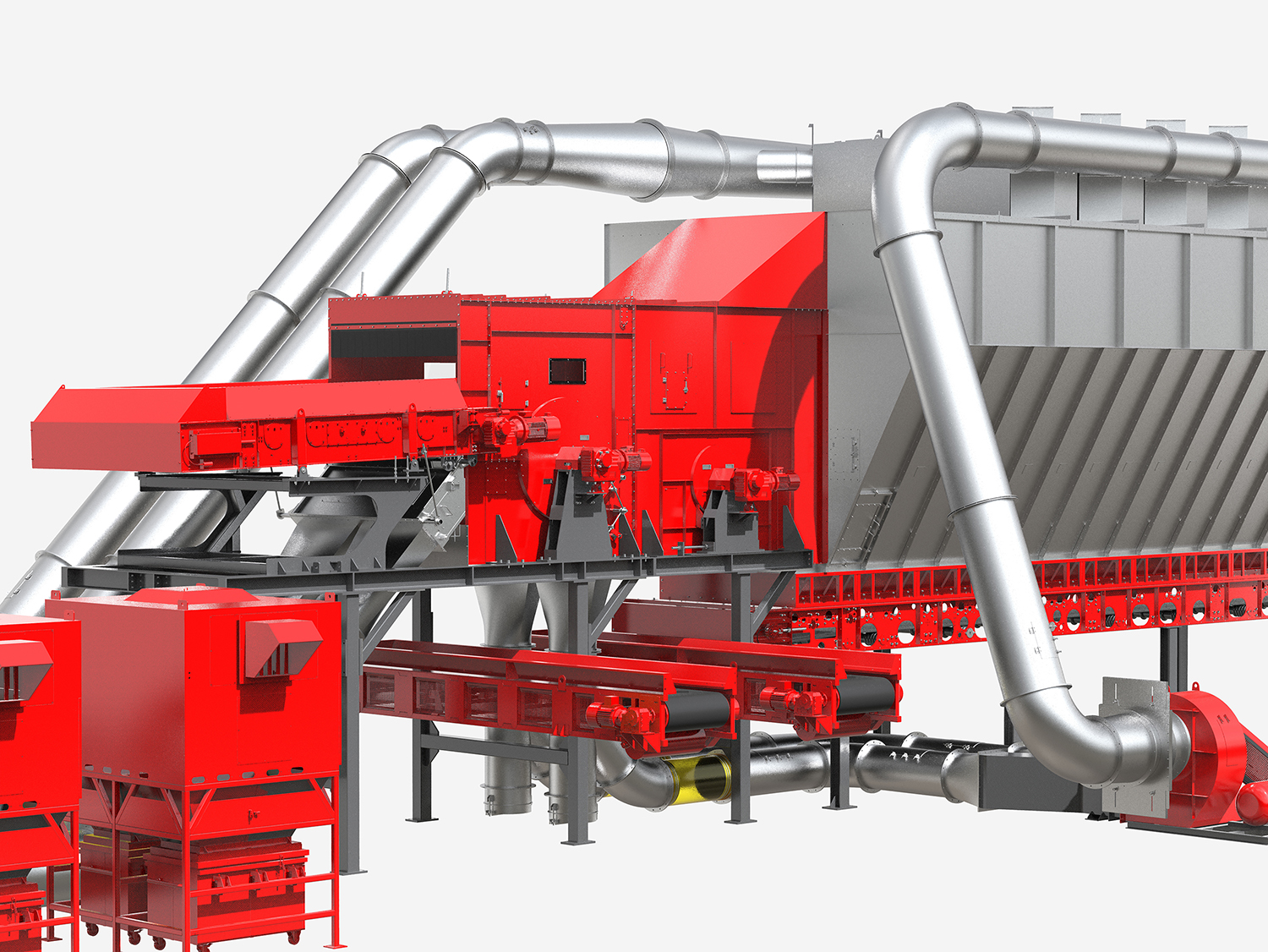

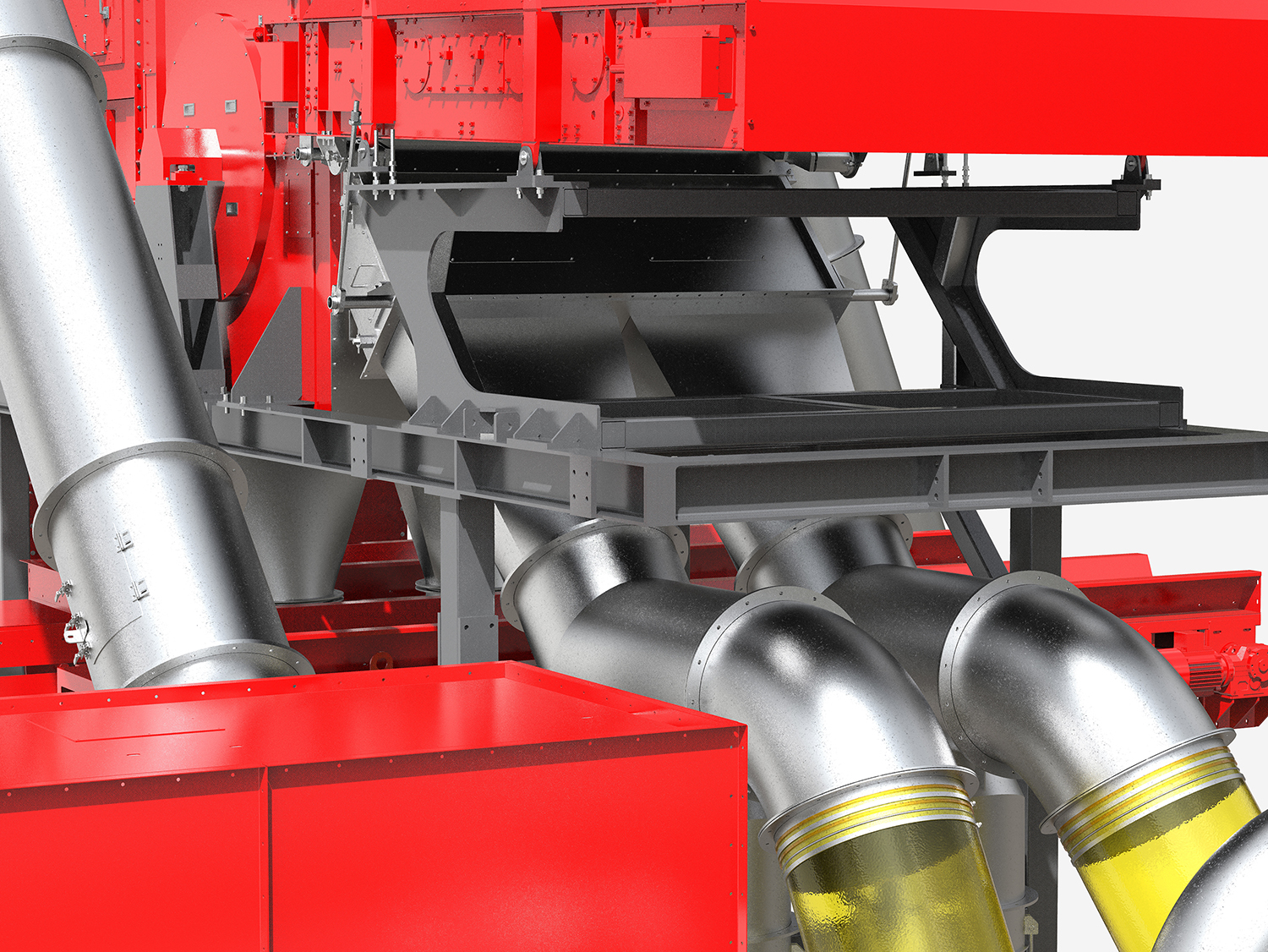

The DDW2000 Double Drum Windshifter is a high-performance air separation system developed by Harden for solid waste recycling and RDF/SRF production. With its dual-drum structure and closed-loop airflow design, the system accurately separates mixed waste into three fractions (light, medium, and heavy).

Its double-drum configuration supports continuous, high-volume processing and maintains stable performance when handling flexible, elongated, or bulky materials. It is an essential piece of equipment for large-scale solid waste pre-treatment and resource recovery operations.

What Distinguishes the

Double Drum Windshifter

What distinguishes

200m³/h

Maximum Throughput Capacity

134kw

Installed Power

2000mm

Working Width

What Materials Can Be Separated?

Shredded materials

Advantages at a Glance

Advantages

Specific Parameter

-

DDW2000Working Width (mm)2000Throughput (m³/h)200Particle Size (mm)20-600View MoreInstalled Power(kw)134Dimensions(mm)30000x10700x8000Weight(kg)32000

Download the brochure

Windshifter.pdf

Perfect Solid Waste Solution

Custom-made solution

For special requirements, we offer the custom-made solution!

Recommendations

Recommendations